In the fast-paced world of manufacturing, staying ahead of the competition requires continuous innovation and adaptation. One of the most significant advancements in this realm is the use of special purpose machinery. Special purpose machinery is designed to perform specific tasks that standard equipment cannot handle efficiently. This blog explores how special purpose machinery is revolutionizing production processes and transforming industry standards, setting new benchmarks for efficiency, precision, and customization.

What Is Special Purpose Machinery?

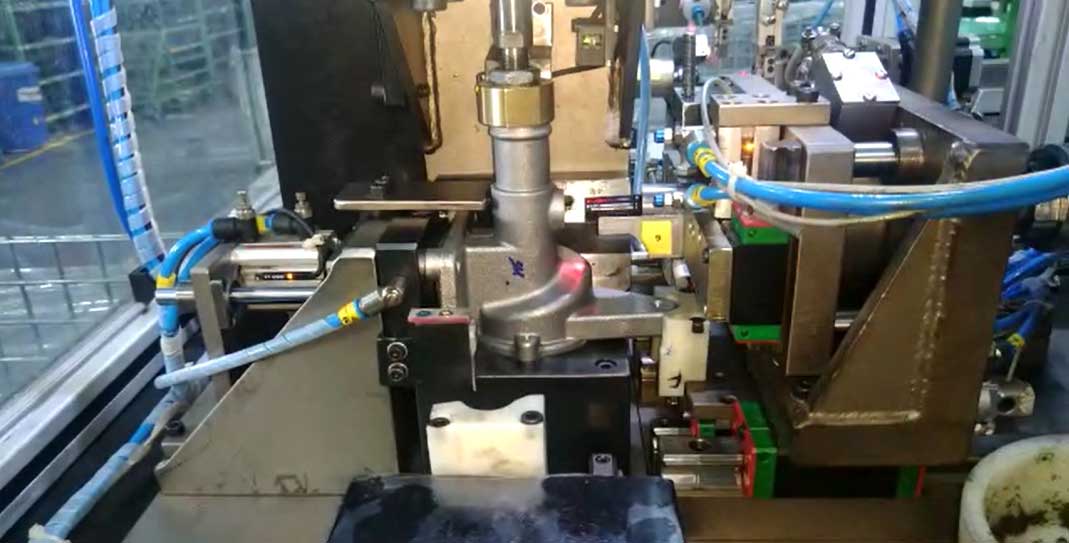

Special purpose machinery refers to equipment that is tailored to perform specific, non-standard tasks in manufacturing processes. Unlike general-purpose machines that can handle a wide range of applications, special purpose machinery is engineered to meet particular production needs. These machines are designed to enhance efficiency, improve product quality, and optimize production workflows.

Special purpose machinery can range from automated assembly lines to complex robotic systems, and they are used across various industries, including automotive, aerospace, electronics, and consumer goods. The primary goal of these machines is to address unique production challenges and deliver customized solutions that general-purpose equipment cannot achieve.

Key Benefits of Special Purpose Machinery

1. Enhanced Efficiency and Productivity

One of the most significant benefits of special purpose machinery is its ability to enhance efficiency and productivity. These machines are designed to perform specific tasks with high speed and precision, reducing the time required for production and increasing overall output. For example, a special purpose machine designed for high-speed assembly can significantly reduce assembly time compared to a standard assembly line, leading to higher production rates and lower operational costs.

By automating repetitive and time-consuming tasks, special purpose machinery minimizes manual labor and human error, allowing manufacturers to achieve consistent and reliable results. This increased efficiency enables companies to meet growing demand and scale production without compromising on quality.

2. Improved Product Quality and Consistency

Special purpose machinery is engineered to deliver exceptional precision and consistency in production. These machines are built to adhere to exact specifications and tolerances, ensuring that each product meets the highest quality standards. Unlike manual processes, where variability and human error can lead to inconsistencies, special purpose machinery provides reliable and repeatable results.

Advanced technologies, such as sensors and control systems, are often integrated into special purpose machinery to monitor and adjust the production process in real-time. This capability helps detect and correct defects or deviations, ensuring that every product is manufactured to the same high standard. As a result, manufacturers can reduce the risk of defective products and minimize costly rework or recalls.

3. Customization and Flexibility

Special purpose machinery offers unparalleled customization and flexibility, allowing manufacturers to tailor equipment to their specific production needs. Whether it’s adapting a machine to handle unique components or modifying it to accommodate different production volumes, special purpose machinery can be designed to meet a wide range of requirements.

This flexibility is particularly valuable in industries where product designs and production requirements frequently change. For instance, a special purpose machine can be reconfigured to handle new product lines or variations, enabling manufacturers to respond quickly to market demands without significant downtime or retooling.

4. Cost Savings and Return on Investment

While the initial investment in special purpose machinery can be substantial, the long-term cost savings often justify the expense. Automated systems reduce labor costs by minimizing the need for manual workers and reallocating human resources to more strategic roles. Additionally, special purpose machinery can lead to significant savings in material costs by reducing waste and optimizing resource utilization.

For example, precise handling and placement of components by special purpose machinery reduce the likelihood of damage or misalignment, resulting in fewer material losses. Over time, these cost savings contribute to a positive return on investment (ROI), making special purpose machinery a financially sound choice for many manufacturers.

5. Enhanced Safety and Ergonomics

Safety is a critical concern in manufacturing, and special purpose machinery plays a significant role in improving workplace safety. By automating hazardous or repetitive tasks, such as heavy lifting or high-speed operations, manufacturers can reduce the risk of workplace injuries and accidents.

Special purpose machinery can handle dangerous or strenuous tasks, minimizing the physical strain on employees and creating a safer work environment. Moreover, automation reduces the need for manual labor and repetitive motions, leading to improved ergonomics and overall job satisfaction for workers.

How Special Purpose Machinery is Transforming Industry Standards

1. Driving Innovation in Manufacturing

Special purpose machinery is at the forefront of innovation in manufacturing, enabling the development of new production techniques and processes. By integrating advanced technologies, such as robotics, artificial intelligence, and machine learning, special purpose machinery is pushing the boundaries of what is possible in production.

For example, the use of collaborative robots (cobots) in assembly lines allows for greater flexibility and interaction between humans and machines. These robots can work alongside human operators, enhancing productivity and safety while performing complex tasks with high precision.

2. Enhancing Sustainability and Environmental Impact

Special purpose machinery is also contributing to sustainability and environmental goals in manufacturing. By optimizing production processes and reducing waste, these machines help minimize the environmental impact of manufacturing operations. For instance, advanced material handling systems can reduce the amount of scrap material generated during production, leading to more efficient resource utilization.

Moreover, energy-efficient special purpose machinery can help manufacturers lower their energy consumption and reduce their carbon footprint. As environmental regulations become more stringent, adopting sustainable practices through special purpose machinery is becoming increasingly important for manufacturers.

3. Expanding Market Opportunities

The ability to produce customized and high-quality products with special purpose machinery opens up new market opportunities for manufacturers. Companies can enter niche markets and cater to specific customer needs by offering unique products that standard equipment cannot produce. This adaptability allows manufacturers to differentiate themselves in competitive markets and expand their customer base.

Conclusion

Special purpose machinery is revolutionizing production processes and transforming industry standards by enhancing efficiency, improving product quality, and offering customization and flexibility. As technology continues to advance, the capabilities of special purpose machinery will evolve, driving innovation and shaping the future of manufacturing.

By investing in special purpose machinery, manufacturers can achieve higher productivity, better quality control, and a safer work environment. Embracing these technologies is not just a trend but a strategic move towards a more efficient, profitable, and future-ready manufacturing process. As industry standards continue to evolve, special purpose machinery will play a crucial role in meeting the demands of an increasingly dynamic and competitive market.