In the bustling landscape of industrial innovation, Metal Laser Cutting in Sydney stands out as a cutting-edge technology that redefines how we approach metal fabrication. At Preston Welding and Engineering, we harness the power of laser technology to deliver precision-cutting solutions tailored to various applications, including stainless steel sheets. This blog will explore the advantages of metal laser cutting, its applications, and why choosing the right provider is crucial for your projects.

Understanding Metal Laser Cutting in Sydney

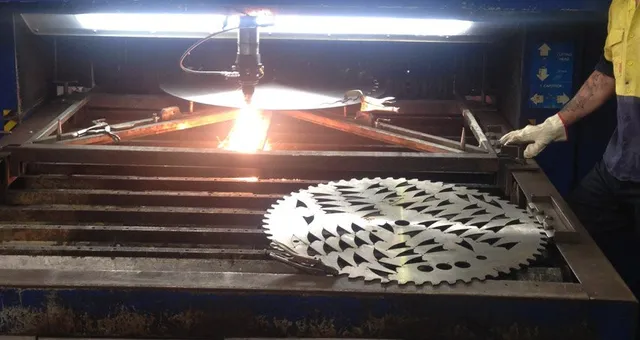

Metal laser cutting is a process that uses focused laser beams to cut through various types of metal with high precision. This technology has revolutionized the metal fabrication industry, allowing for intricate designs and clean cuts that traditional methods cannot achieve.

How Metal Laser Cutting Works

The process involves directing a high-powered laser beam onto the metal surface. As the beam heats the metal, it melts or vaporizes, creating a precise cut. This method is not only efficient but also minimizes waste and reduces the need for secondary operations.

Benefits of Metal Laser Cutting

- Precision and Accuracy: Metal laser cutting provides unparalleled accuracy, making it ideal for complex designs and tight tolerances.

- Versatility: This technology can cut a variety of metals, including stainless steel, aluminum, and carbon steel.

- Minimal Material Waste: The focused laser beam reduces excess material, allowing for cost-effective fabrication.

- Faster Turnaround Times: Laser cutting is typically quicker than traditional cutting methods, reducing lead times for projects.

Applications of Metal Laser Cutting in Sydney

Metal laser cutting has a wide range of applications across various industries. Here are some common uses:

1. Fabrication of Stainless Steel Sheets

One of the most popular applications of metal laser cutting is in the fabrication of Stainless Steel Sheets in Sydney. The precise cuts and clean edges achieved through laser cutting are essential for creating components used in everything from architectural designs to kitchen appliances.

2. Automotive Industry

The automotive industry benefits significantly from laser cutting technology, as it allows for the production of lightweight, high-strength components. This is crucial for enhancing fuel efficiency and overall vehicle performance.

3. Aerospace Sector

In aerospace, precision is paramount. Metal laser cutting is employed to manufacture complex parts that must meet strict regulatory standards while maintaining lightweight characteristics.

4. Art and Design

Artists and designers utilize metal laser cutting to create intricate sculptures, decorative panels, and custom signage. The versatility of this technology enables unique and customized creations that stand out.

Choosing the Right Provider for Metal Laser Cutting in Sydney

Selecting the right provider for metal laser cutting in Sydney is crucial for the success of your projects. Here are some factors to consider when making your choice:

Experience and Expertise

Look for a company with a proven track record in metal laser cutting. Experience ensures that the provider understands the nuances of the process and can deliver high-quality results.

Equipment and Technology

Ensure that the provider uses state-of-the-art laser cutting machines. Advanced technology leads to better precision, faster cutting speeds, and the ability to handle various materials, including stainless steel sheets.

Customization Options

Your projects may require specific cuts and designs. Choose a provider that offers customization options to meet your unique needs.

Customer Support

A reliable provider should offer excellent customer support, guiding you through the entire process and addressing any concerns you may have.

The Process of Metal Laser Cutting at Preston Welding and Engineering

At Preston Welding and Engineering, we take pride in our meticulous approach to metal laser cutting. Here’s a step-by-step overview of our process:

Step 1: Consultation and Design

We start with a consultation to understand your needs and design requirements. Our team will work closely with you to create detailed drawings or CAD files.

Step 2: Material Selection

Once the design is finalized, we assist you in selecting the appropriate materials, including high-quality stainless steel sheets, to ensure optimal results.

Step 3: Laser Cutting

Using advanced laser cutting machines, we perform the cutting process with precision, ensuring clean edges and accurate dimensions.

Step 4: Quality Control

After cutting, each piece undergoes a rigorous quality control process. We inspect the components to ensure they meet our high standards and your specifications.

Step 5: Delivery

Finally, we arrange for timely delivery of your finished products, ensuring they arrive in perfect condition and on schedule.

Why Choose Preston Welding and Engineering for Your Metal Laser Cutting Needs?

Expertise and Quality Assurance

At Preston Welding and Engineering, we combine years of experience with cutting-edge technology to provide top-notch metal laser cutting services in Sydney. Our commitment to quality ensures that you receive only the best products for your projects.

Comprehensive Services

We offer a wide range of services beyond laser cutting, including welding, fabrication, and assembly. This comprehensive approach allows us to meet all your metalworking needs under one roof.

Customer-Centric Approach

Our clients are our priority. We work closely with you throughout the entire process, ensuring your vision is realized. Our responsive customer support is always available to address your questions and concerns.

The Future of Metal Laser Cutting

As technology continues to evolve, so does the future of metal laser cutting. Innovations such as fiber lasers and automation are set to enhance efficiency, reduce costs, and improve the quality of cuts. Staying at the forefront of these advancements allows us to provide our clients with the best solutions for their metal fabrication needs.

Conclusion

In conclusion, metal laser cutting in Sydney is a game-changer for the metal fabrication industry, offering precision, versatility, and efficiency. At Preston Welding and Engineering, we are committed to harnessing this cutting-edge technology to deliver high-quality solutions, including stainless steel sheets and more. By choosing the right provider, you can ensure your projects are executed flawlessly, setting the stage for success.

FAQs about Metal Laser Cutting in Sydney

Q1: What materials can be cut using metal laser cutting?

A1: Metal laser cutting can be used on various materials, including stainless steel, aluminum, carbon steel, and other metals.

Q2: How does metal laser cutting differ from traditional cutting methods?

A2: Metal laser cutting uses focused laser beams for precision cutting, while traditional methods may involve blades or saws, which can be less accurate.

Q3: Can Preston Welding and Engineering handle custom designs?

A3: Yes, we specialize in custom designs and work closely with clients to meet their specific needs.

Q4: What are the advantages of using stainless steel sheets for fabrication?

A4: Stainless steel sheets offer durability, corrosion resistance, and a polished finish, making them ideal for various applications.

Q5: How can I request a quote for metal laser cutting services?

A5: You can contact us directly through our website or give us a call, and our team will be happy to provide you with a quote based on your project specifications.

By choosing Preston Welding and Engineering for your metal laser cutting needs, you’re investing in quality, precision, and a commitment to excellence that will elevate your projects to new heights. Let us help you unlock the potential of your designs with our state-of-the-art technology and dedicated expertise.

Visit: https://techmonarchy.com/