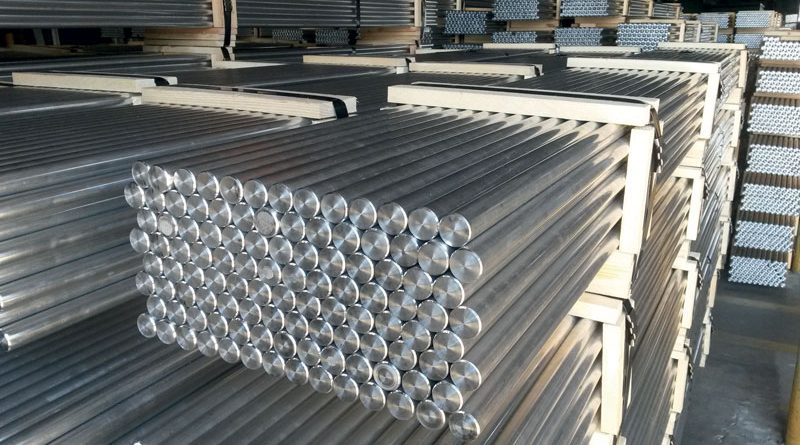

Aluminium round bars are highly valued in various industries for their strength, versatility, and lightweight properties. They are integral to construction, automotive, aerospace, and manufacturing projects. This detailed guide explores aluminium round bars’ strength, applications, and the factors contributing to their widespread use. We also provide insights into the Aluminium Round Bar Price for those interested in cost considerations.

Understanding the Strength of Aluminium Round Bars

Several factors, including the specific aluminium alloy, the manufacturing process, and the heat treatment applied, influence the strength of an aluminium round bar. The most commonly used aluminium alloys for round bars are 6061, 6063, and 7075. Each alloy has distinct mechanical properties that make it suitable for different applications.

Aluminium Alloy 6061

Aluminium 6061 is one of the most versatile and widely used aluminium alloys. It offers a good balance of strength, corrosion resistance, and machinability. The tensile strength of the 6061 aluminium round bar typically ranges from 35,000 to 45,000 psi, depending on the temperature (heat treatment). This makes it ideal for structural applications in the construction and automotive industries.

Aluminium Alloy 6063

Aluminium 6063, often called the architectural alloy, is known for its excellent corrosion resistance and surface finish. While it is slightly lower than 6061, with tensile strength around 27,000 psi to 30,000 psi, it is still sufficiently strong for many applications. It is commonly used in extrusions, such as window frames, door frames, and irrigation tubing.

Aluminium Alloy 7075

Aluminium 7075 is one of the highest-strength aluminium alloys available, with tensile strengths ranging from 73,000 to 78,000 psi. This alloy is used in applications requiring high strength and toughness, such as aerospace and military industries. Despite its higher cost, the 7075 aluminium round bar is chosen for critical applications where strength cannot be compromised.

Factors Influencing the Strength of Aluminium Round Bars

- Alloy Composition: The elements added to aluminium, such as copper, magnesium, and zinc, significantly affect the alloy’s strength and other mechanical properties.

- Heat Treatment: Heat treatment processes, including tempering and ageing, can enhance the strength and hardness of aluminium round bars.

- Manufacturing Process: Whether the aluminium round bar is extruded, rolled, or drawn impacts its grain structure and, consequently, its strength.

- Cross-Sectional Area: The diameter of the round bar affects its load-bearing capacity. Larger diameters typically offer higher strength for the same material.

- Quality of Manufacture: Adherence to manufacturing standards and quality control processes ensures the produced round bars meet the required strength specifications.

Applications of Aluminium Round Bars

Due to their strength and versatility, aluminium round bars are used in a wide range of applications, including:

- Construction: Structural supports, railings, and frameworks.

- Automotive: Engine components, transmission parts, and chassis.

- Aerospace: Aircraft frames, landing gear, and wing structures.

- Marine: Boat fittings, masts, and marine hardware.

- Manufacturing: Machinery parts, tools, and equipment.

Comparing Aluminium Round Bars with Other Metals

Round aluminium bars are often compared with steel and other metal bars in strength and weight. While steel has higher tensile strength, aluminium’s strength-to-weight ratio is superior. That makes aluminium round bars an excellent choice when weight reduction is critical without compromising strength.

Cost Considerations: Aluminium Round Bar Price

When considering the strength and utility of aluminium round bars, it’s also essential to factor in the cost. The Aluminium Round Bar Price can vary based on the alloy, dimensions, and market conditions. Generally, aluminium round bars offer a cost-effective solution, especially when their lightweight properties lead to savings in transportation and ease of installation.